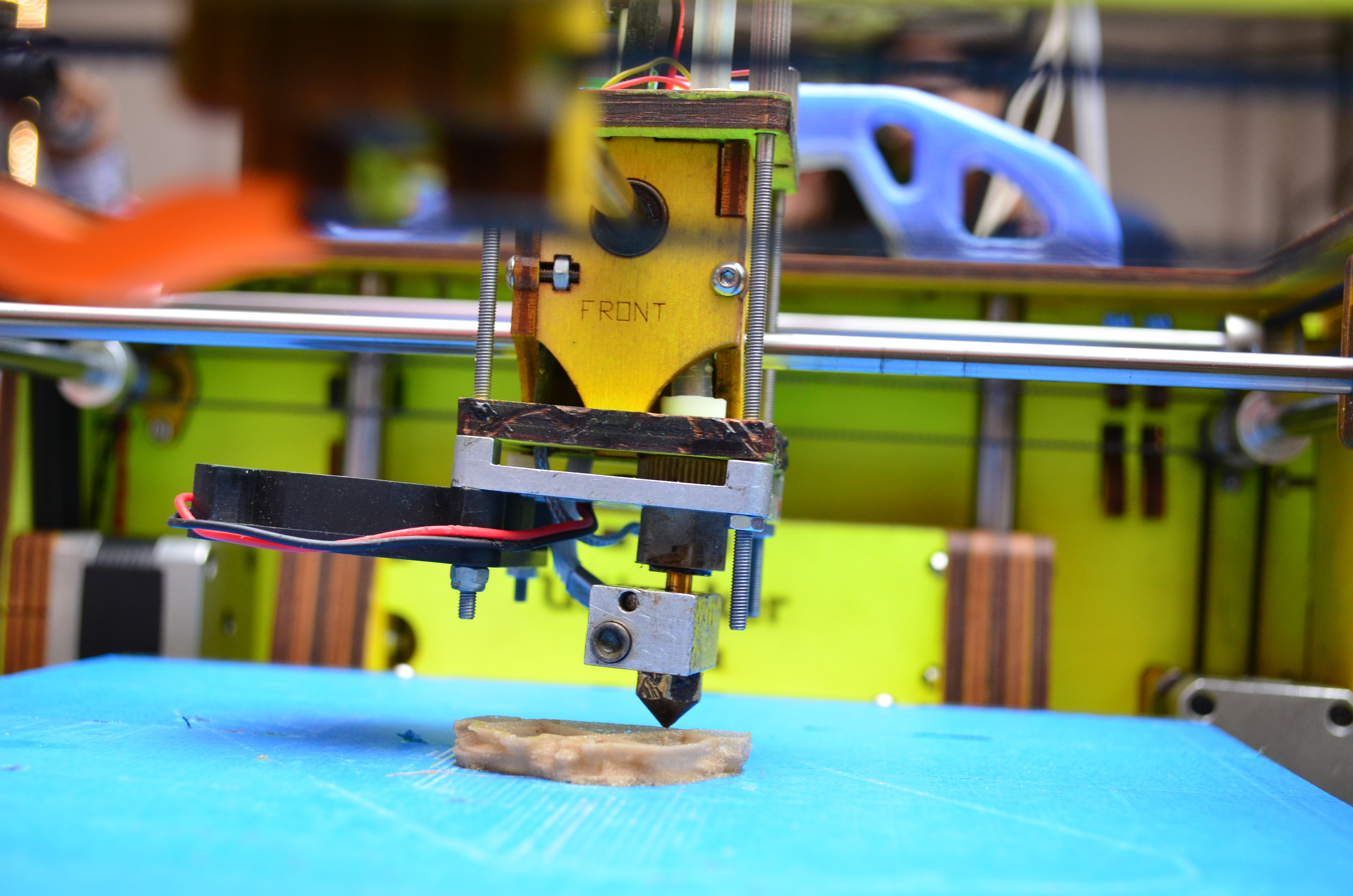

3D-printers have been around for several years, and number of new 3D projects is becoming greater every day. However, industry still see no use in 3D printers - firstly, because of its high cost, and secondly, because of the process’ duration. Besides, most of the modern printers create an object layer-by-layer, applying one layer of material on another, which makes the final product unstable in serious overload. However, this does not mean that large manufacturing companies are not looking for ways to solve these problems. Moreover, they even have had some success in this field.

One of the world's leading automakers, American Ford is actively cooperating with Carbon3D Inc – a startup, supported by Google Ventures, Alphabet’s financial division. The carmaker is already testing Carbon3D’s printers in its own labs, which, according to representatives of the Ford itself, may be the solution to all the problems inherent in the original 3D-printing technology. Unlike typical printers, the Californian company’s new invention, melts sparing parts out of the liquid resin, letting light beams flow through it. In addition, this method of 3D-printing takes much less time compared to the standard technology. It allows creating items, in no way inferior in their strength to those made in the factories, explained Ellen Lee, heads Ford's division working with 3D- printing. However, even all the technology’s advantages do not outweigh its excessive cost, what makes the invention impossible in industrial use. "The main problem is that if we want to produce 100 thousand cars, each of which requires a lot of different parts, it is too expensive to create of each of them using the 3D-printing... more expensive than conventional methods", - explained Ms. Lee.

Ford is not the only large company currently looking for ways to introduce the printing technology into mass production. For example, General Electric announced that its intention to create up to 200 thousand fuel guns for its aviation business using the 3D-printing. Recently, the company's management reported about establishment of a special R&D center in Pittsburgh, which will focus on the search for the possible use of new technology in all business structures of the American corporation.

There is also Siemens, which scientific laboratory in Princeton recently introduced an autonomously operating robo-spider 3D-printer. Each printer is equipped with mechanical claws that allow the device to move around. Moreover, thanks to a specially developed algorithm, the SiSpis printers (Siemens Spiders) are able to perform team work to create a single subject. Each robot gets a certain part of the work and proceeds to perform a certain task. This approach allows making large-scale items - from car bodies to airplanes fuselages.

Now, companies around the world infuse about $ 1.5 billion in the 3D-printing researches. For comparison, when 3D printing technology was just introduced in 2012, only $ 406 million had been spent in this industry. Gartner research agency estimated that by 2017, worldwide research in this area would take $ 4 billion annually.

source: wsj.com

One of the world's leading automakers, American Ford is actively cooperating with Carbon3D Inc – a startup, supported by Google Ventures, Alphabet’s financial division. The carmaker is already testing Carbon3D’s printers in its own labs, which, according to representatives of the Ford itself, may be the solution to all the problems inherent in the original 3D-printing technology. Unlike typical printers, the Californian company’s new invention, melts sparing parts out of the liquid resin, letting light beams flow through it. In addition, this method of 3D-printing takes much less time compared to the standard technology. It allows creating items, in no way inferior in their strength to those made in the factories, explained Ellen Lee, heads Ford's division working with 3D- printing. However, even all the technology’s advantages do not outweigh its excessive cost, what makes the invention impossible in industrial use. "The main problem is that if we want to produce 100 thousand cars, each of which requires a lot of different parts, it is too expensive to create of each of them using the 3D-printing... more expensive than conventional methods", - explained Ms. Lee.

Ford is not the only large company currently looking for ways to introduce the printing technology into mass production. For example, General Electric announced that its intention to create up to 200 thousand fuel guns for its aviation business using the 3D-printing. Recently, the company's management reported about establishment of a special R&D center in Pittsburgh, which will focus on the search for the possible use of new technology in all business structures of the American corporation.

There is also Siemens, which scientific laboratory in Princeton recently introduced an autonomously operating robo-spider 3D-printer. Each printer is equipped with mechanical claws that allow the device to move around. Moreover, thanks to a specially developed algorithm, the SiSpis printers (Siemens Spiders) are able to perform team work to create a single subject. Each robot gets a certain part of the work and proceeds to perform a certain task. This approach allows making large-scale items - from car bodies to airplanes fuselages.

Now, companies around the world infuse about $ 1.5 billion in the 3D-printing researches. For comparison, when 3D printing technology was just introduced in 2012, only $ 406 million had been spent in this industry. Gartner research agency estimated that by 2017, worldwide research in this area would take $ 4 billion annually.

source: wsj.com